Enterprise Asset Management: Getting the Most From Your CMMS

Efficient enterprise asset management (EAM) ensures your organization has the tools it needs to succeed. Optimizing performance and maintenance for your assets is paramount, and a robust Computerized Maintenance Management System (CMMS) plays a pivotal role in maximizing the full potential of your CMMS.

Enterprise asset management encompasses the strategic approach of overseeing and maintaining an organization's assets throughout its lifecycle. At the core of this process lies the CMMS, a software solution designed to streamline work orders, track asset performance, and simplify maintenance operations. By harnessing the power of CMMS solutions, facilities managers can enhance operational efficiency, reduce downtime, and extend the lifespan of their assets.

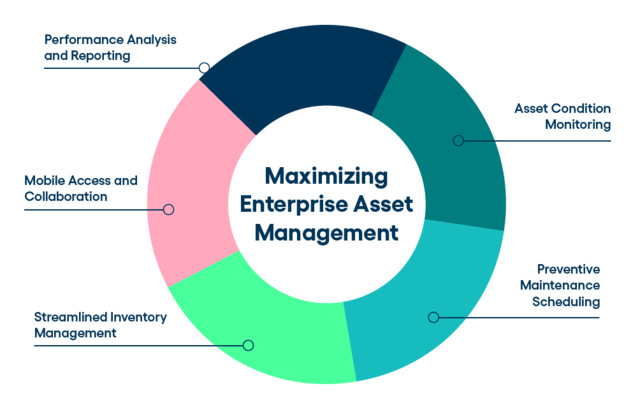

The benefits of CMMS software, from automated work order management to proactive maintenance scheduling, highlight how a CMMS can revolutionize your asset management practices. Five key EAM tools allow you to unlock the full potential of your CMMS, empowering your facility management team and giving them the tools they need to thrive.

1. Asset condition monitoring

Asset condition monitoring has emerged as a game-changer for organizations seeking to proactively manage physical assets. By integrating asset sensors, data analytics, and real-time monitoring capabilities, businesses gain the power to monitor asset conditions in a proactive and predictive manner.

Using EAM software, organizations can track various condition indicators including temperature, vibration, pressure, and humidity, all critical data points that help assess asset health and predict potential failures. By continuously collecting and analyzing this detailed data, organizations gain valuable insights into asset behavior, allowing them to optimize maintenance strategies, minimize downtime, and extend asset life cycles.

Integrating asset sensors and real-time monitoring capabilities enable organizations to move away from reactive maintenance practices and toward proactive asset management. Instead of relying solely on reactive work requests, EAM software helps facilities managers monitor assets in real-time and detect early warning signs of potential issues. By staying ahead of problems and addressing them before they escalate, organizations can significantly reduce unexpected breakdowns and associated costs.

In addition, the wealth of data collected through asset condition monitoring gives critical context for making strategic long-term decisions. When you understand how assets behave under different conditions, you can optimize maintenance schedules, allocate resources effectively, and make informed decisions on asset repair, replacement, and upgrades. This holistic approach to asset management ultimately results in improved asset performance, reliability, and longevity.

2. Preventive maintenance scheduling

EAM software is crucial in optimizing preventive maintenance scheduling. Preventive maintenance leads to:

- Increased productivity: Regularly maintaining assets ensure they operate at peak efficiency, reducing the risk of unexpected breakdowns and productivity interruptions.

- Minimized asset downtime: Proactively scheduled maintenance reduces unplanned downtime, enabling organizations to maintain operational continuity and meet production targets.

- Cost reduction: Preventive maintenance helps identify potential issues early on, preventing costly repairs or replacements, and reducing overall maintenance costs.

- Enhanced safety: By regularly inspecting and maintaining equipment, organizations can mitigate safety risks, ensuring a safer working environment for employees.

Proactively planning and executing maintenance tasks prevents equipment failures, which maximizes asset performance, and ensures asset reliability and longevity. A preventive maintenance schedule eliminates reactive maintenance, which focuses on addressing issues after they occur.

Enterprise Asset Management software provides a range of features that optimize preventive maintenance scheduling, including:

- Real-time access to maintenance tasks: EAM software allows facilities managers to access and monitor maintenance tasks in real time, ensuring timely execution and preventing delays.

- Automated work order scheduling: EAM software streamlines the scheduling process by automating work order creation, assignment, and tracking, ensuring efficient allocation of resources.

- Historical data analysis: EAM software captures and analyzes maintenance data, enabling organizations to identify patterns, trends, and failure modes, which aids in fine-tuning preventive maintenance schedules.

By leveraging the capabilities of EAM software, organizations can effectively manage preventive maintenance tasks, reduce asset downtime, cut costs, and promote a safer working environment, ultimately optimizing maintenance work and enhancing overall operational efficiency.

3. Streamlined inventory management

EAM (Enterprise Asset Management) software is a valuable tool for streamlining inventory management processes and overcoming the challenges associated with it. Inventory management can be a complex process that involves procuring, storing, tracking, and using various parts and supplies. EAM optimizes inventory management by:

- Preventing equipment failure: EAM software ensures the availability of critical spare parts and supplies. By maintaining accurate inventory records and implementing preventive maintenance schedules, organizations can proactively address equipment issues and minimize downtime.

- Automating inventory tracking: Automating inventory tracking, EAM provides real-time visibility into stock levels, locations, and usage. This eliminates the need for manual tracking methods and reduces the risk of stockouts or overstocking.

- Optimizing inventory levels: EAM software enables organizations to establish optimal inventory levels based on historical data, usage patterns, and maintenance requirements. This helps prevent excess inventory and associated carrying costs while ensuring sufficient stock for maintenance and repairs.

EAM software streamlines inventory management through:

- Real-time inventory counts: EAM software provides real-time visibility into inventory levels, allowing facilities managers to track stock in real time and make informed decisions regarding replenishment.

- Detailed inventory reports: EAM software generates comprehensive inventory reports, including stock levels, usage history, reorder points, and lead times. These reports enable facilities managers to analyze inventory trends and make data-driven decisions.

- Integration with procurement systems: EAM software can integrate with procurement systems, automating the purchase order process and ensuring seamless replenishment of inventory when stock levels reach predetermined thresholds.

By leveraging the capabilities of EAM software for inventory management, organizations can optimize stock levels, reduce the risk of equipment failure, minimize carrying costs, and improve overall efficiency in managing inventory.

4. Mobile access and collaboration

EAM (Enterprise Asset Management) systems offer significant advantages in fostering better collaboration among maintenance teams. With modern CMMS software solutions being cloud-based and accessible via mobile devices, team members can access critical asset information anywhere, anytime.

This accessibility enhances collaboration by providing real-time access to relevant data. Maintenance team members can retrieve and update work orders, access asset information, view maintenance history, and track inventory levels all from their mobile devices.

A mobile-friendly CMMS facilitates seamless collaboration across teams by enabling real-time communication, allowing team members to update work orders, input data on-the-go, and share information instantaneously. The ability to collaborate remotely promotes better accuracy, as team members can provide real-time updates and receive immediate feedback. It also increases efficiency by reducing manual paperwork and eliminating the need for team members to be physically present at a central location.

Overall, leveraging EAM for better collaboration through a mobile-friendly CMMS streamlines communication, improves accuracy, and enhances the efficiency of maintenance operations.

5. Performance analysis and reporting

Enterprise Asset Management systems provide organizations with a powerful tool for performance analysis and reporting, enabling them to gain valuable insights into asset performance metrics. Use your CMMS to generate detailed reports that assess and monitor key performance indicators (KPIs).

- Asset utilization: EAM software can track and report on your organization’s asset utilization rate, providing insights into their efficiency and identifying potential areas for improvement.

- Maintenance costs: Detailed reports on maintenance costs help organizations analyze spending patterns, identify cost-saving opportunities, and optimize budget allocation.

- Work order progress: EAM software captures data on work order status, enabling the monitoring of progress, identifying bottlenecks, and improving overall work order management efficiency.

By leveraging performance analysis and reporting capabilities, organizations can:

- Identify trends: Through the analysis of performance metrics, organizations can identify patterns and trends, enabling them to make informed decisions about maintenance strategies and asset management practices.

- Benchmark performance: EAM software facilitates the comparison of performance metrics against industry standards or internal benchmarks, providing a benchmark for evaluating and improving asset performance.

- Make data-driven decisions: The availability of accurate and comprehensive performance reports empowers organizations to make strategic decisions based on real-time data, leading to more effective resource allocation and optimized maintenance practices.

By utilizing EAM software for performance analysis and reporting, organizations can gain valuable insights into asset performance, identify areas for improvement, benchmark performance against industry standards, and make data-driven decisions that enhance operational efficiency and maximize asset performance.

Take your enterprise asset management to the next level with Brightly Software

Enterprise Asset Management goes beyond work order management and is a valuable tool for organizations that use it to its full potential. To learn all the benefits of CMMS and how EAM can help your organization, contact a Brightly expert.